In the context of globalization, compliance with international standards is not only a “passport” enabling products to access foreign markets but also a measure of enterprise credibility and quality. In particular, for the construction brick and cladding tile sector, CE certification is a mandatory condition for products to be legally placed on the European Union (EU) market.

According to the EU Construction Products Regulation (CPR) (Regulation (EU) No 305/2011), all construction products, including ceramic bricks, concrete bricks, and cladding tiles, are required to bear the CE marking. This is not only a legal requirement but also evidence that the product fully meets international standards relating to safety, quality, and performance.

Benefits of obtaining CE certification

Some benefits when enterprises obtain CE certification

-

Market expansion: Enterprises have the opportunity to export to all 27 EU member states without legal barriers.

-

Enhanced brand credibility: Products bearing the CE marking are assessed as having higher quality, increasing competitiveness in the international market.

-

Long-term cost optimization: Standardizing processes and products in accordance with CE requirements helps reduce technical errors and save operational costs.

-

Protection against legal risks: Products without CE marking may be subject to recall, prohibition of circulation, or significant penalties within the EU.

To achieve the above benefits, enterprises are required to undergo a rigorous and systematic CE certification process. This is not only a legal procedure but also a process that supports product standardization and ensures quality and safety for placement on the European market.

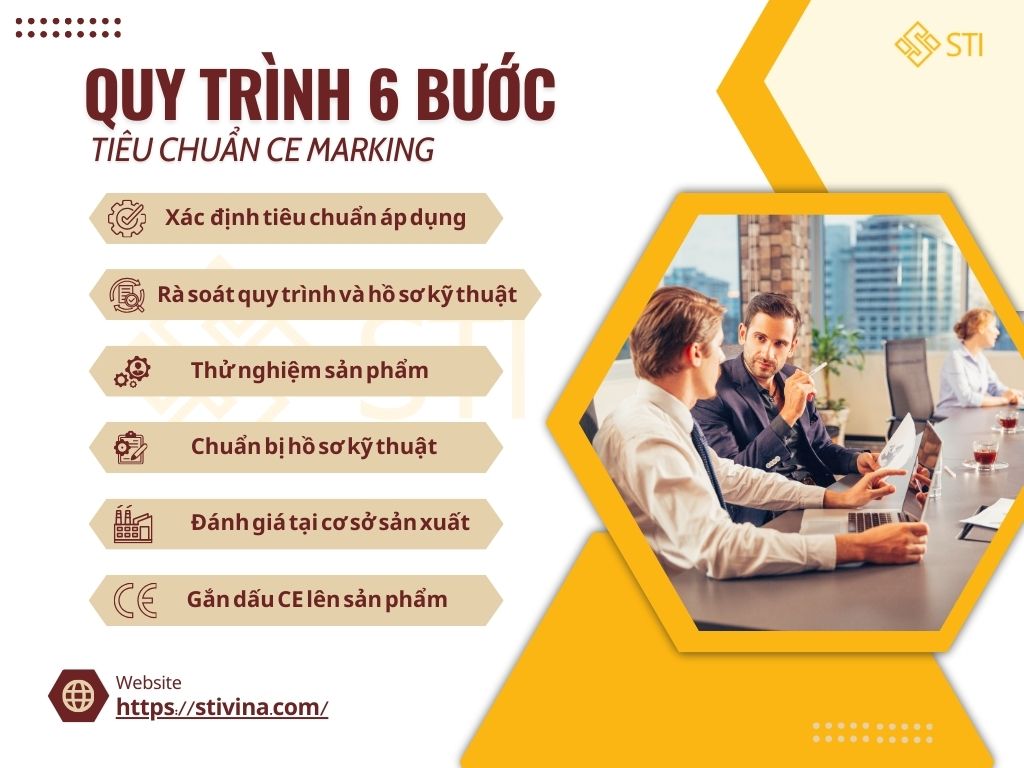

CE certification process for bricks

This process is not limited to product testing but also includes a comprehensive review of applicable standards, production management systems, and technical documentation. It is a structured pathway in which each step affects the final outcome.

Process to obtain CE marking certification

Step 1: Identification of applicable standards

The enterprise is first assessed based on the type of brick products it manufactures, after which the appropriate EN standards in accordance with EU regulations are selected. For example, ceramic bricks are subject to EN 14411, while concrete blocks must comply with EN 771-3. Correct identification at the outset helps avoid errors and significantly saves time throughout the process.

Step 2: Completion of production systems and technical documentation

After determining the applicable standards, the existing production system is reviewed and assessed. The enterprise is guided to adjust processes and prepare technical documentation to comply with mandatory EU requirements.

Step 3: Product testing

Brick samples are tested at an accredited laboratory (ISO/IEC 17025) against parameters such as water absorption, flexural strength, abrasion resistance, and impact resistance.

Step 4: Establishment of technical documentation

The Technical File is completed, including test results, product descriptions, production processes, instructions for use, and the CE label.

Step 5: Assessment at the manufacturing site

An independent assessment team conducts an on-site inspection of the factory to confirm stable production processes and product conformity with standards.

Step 6: Affixing the CE mark

Once approval is granted, the enterprise is authorized to affix the CE mark to the product or packaging and formally declare conformity, while assuming responsibility for maintaining quality in accordance with the commitment.

Notes during implementation

The CE process requires accuracy at each step, particularly in selecting applicable standards, preparing documentation, and coordinating with testing organizations. If implemented independently, enterprises may incur additional time and costs for revisions and repeated testing.

Common difficulties encountered by enterprises

Difficulties faced by enterprises during implementation

-

Uncertainty regarding applicable standards: Each type of brick corresponds to different EN standards, which may cause confusion.

-

Lack of knowledge regarding technical documentation: The Technical File requires detailed and accurate information; omission of any item may result in rejection.

-

High testing costs: If an appropriately accredited laboratory is not selected, test results may be deemed invalid.

-

Challenges in working with a Notified Body (EU certification body): This may prolong timelines and increase costs.

Solutions from STI Viet Nam

With experience supporting numerous construction materials manufacturers, STI Viet Nam provides comprehensive CE certification consultancy services:

-

Preliminary assessment and consultation for each brick product type.

-

Product testing at laboratories compliant with EU standards.

-

Preparation of technical documentation, declaration of performance (DoP), and CE labeling.

-

Guidance on internal production control in accordance with standard requirements.

-

Direct coordination with Notified Bodies to reduce certification timelines.

-

Training and transfer of CE processes to factory personnel.

STI Viet Nam – accompanying Vietnamese enterprises in accessing international markets.

STI commitments

STI has a team of specialists with in-depth knowledge of construction materials standards and the EU market, along with close cooperation with international certification bodies. STI commits to supporting enterprises until full completion of CE certification, with solutions that are timely, flexible, and cost-optimized.

CE certification is not only a passport enabling Vietnamese brick products to enter the European market but also a milestone in enhancing international market credibility. With the support of STI Viet Nam, a process often regarded as complex becomes transparent, manageable, and effective, enabling enterprises to confidently expand markets and strengthen their position.

Contact STI for detailed consultation and to begin the process of accessing the European market.